ALLHone Honer

Innovative handheld sharpening apparatus for a shaving sharp blade edge. Born from the need for light, compact and versatile edge sharpeners for uses from home or workplace to remote wilderness.

In very little time without much skill anyone can create these polished mirror shine convex and straight edge shapes that are super sharp with an ALLHone edge honer.

The ALLHone honer fitted with diamond, silicon oxide polyester film or a ribbon of silicon carbide, aluminum oxide sand paper from your local store both sharpens and replicates the finishing hone of traditional leather strops.

A great combination 800 to 1000 on the frequent change side and 2000 and finer on the opposing side. The coarse side gives the edge micro teeth and after a little stropping on the fine side you will produce an ultra sharp shaving and cutting edge. Recommend 18 degrees angle.

Diamond abrasives on film produces a more polished surface compared to a hard diamond stone due diamonds are more deeply embedded into the film surface for durability than the electroplated diamonds onto a hard surface. So the film surface is less abrasive and polishes.

Silicon carbide breaks down from a pyramid shape into a smaller pyramid so its is practically preferable to use 2000 grit for polishing due to after initial use removing metal it’s points break off producing a smaller pyramid, thereafter a finer grit for polishing. Aluminum oxide polishes well and breaks down slower than silicon carbide but is not as fast at removing metal material initially when the silicon carbide pyramid has not yet broken from use.

Available at www.bootsandgear.nz

ALLHONE twin diamond straight edge sharpener.

Weighs only 105gms.

2 opposing diamond stones permanently bonded with a heat resistant adhesive onto tough and heat resistant ASA.

Born from the need for improved light, compact and versatile edge sharpeners for uses from home or workplace to remote wilderness.

In bright easy to find orange and pocket sized only approx 14 cm long. 65 gms light weight due to the handle is hollow.

Diamond stone surfaces approx 75mm x 30mm.

ALLHONE twin Angle Sharpener handle has opposing flat surfaces that consistently align a blade angle and this speeds up resharpening.

- Options; 17.5 deg for around 2.5 mm spine farming/butcher knives of Victory, Victorinox, Swibo etc.

- 15 deg for Mercators which have a 3mm wide spine.

- 12.5 deg for 4 to 5mm spine or have a bevel, usually high end Italian folders etc or survival bush ones like our Manly Eagle.

240 and 1200 grit is a common combo for what is known in the sharpening fraternity as a work edge a hunter will love.

180/1200 grit stones are sold by Mercator Germany for their knives.

We supply 240 grit and if that still sounds too coarse for you well let me explain that diamond stones including expensive USA ones quickly lose the outstanding grits as they get knocked off and lost creating a more uniform level field of grit height within a few resharpenings and produces what is known as a working edge, toothy just like a steak knife on a micro scale.

You will get shaving sharp on the 1200 stone gauranteed.

We also offer it in 1000/3000 for those that like doing extra fine edges in the 15 deg for low angle.

Not sure that you are resharpening at the best angle every time? This tool fixes this problem without the need of complicated devices to help you achieve a consistent resharpening angle and save time in the process instead wasting time removing shoulder steel instead of sharpening the actual edge angle.

Available at www.bootsandgear.nz

ALLHONE Mercator diamond sheath designed for the MERCATOR knife.

This new and novel sheath snuggly fits all the famed Mercator pocket knives from Germany. A household name among the hunting fraternity for over a century in NZ.

Features:

The sheath holds the Mercator snuggly without rattle.

A flexible loop fits over 4cm wide belts and with a hook to hold itself onto the belt. Simply clip it the sheath onto the belt and can be removed by flexing the loop creating a gap and manually guiding the belt through the gap.

A hole in the bottom for drainage.

Sheath knife housing is rectangular and easy to clean.

A durable and convenient 2000 grit 75mm x 30mm diamond resharpening stone is mounted into a recess is readily available for field sharpening.

Flex open the flexible clip with a retaining hook and remove the sheath from the belt and sharpen the Mercator’s edge on the diamond stone.

Available at www.bootsandgear.nz

ALLHONE 123 ARROW SAW SYSTEM

All designed and made in New Zealand.

Replaces three arrow tools;

1/ check arrow shafts for true tolerance by rotating in the cradles and sort accordingly

2/ cut arrows

3/ sand cut end @ 90 degrees.

Friction force retains three arrow cradles along the aluminum rectangular tube and a respective screw provides adjustment maintaining alignment position during cutting.

Three aligned cradles provide supporting points of contact reducing arrow flex to produce a more precise cut.

As the dremel type saw cutting discs wears down the user skilled in the art re-aligns the arrow cradles at a new cutting position so the arrow end is cut at 90 degrees and the full radius length of the disc is able to be used as it gradually wears down from cutting erosion.

The arrow cradles are also able to be used to check and sort for straight arrow shaft tolerances by rotating the shaft while held in the respective cradles and gauging the arrow’s end movement.

The end cradle includes a slot for holding a piece of sanding material/ sand paper for creating a perfect 90 degree arrow end by rotating the arrow shaft in contact with the abrasive surface until a perfect 90 degree end is produced.

The arrow end may also be finished by orientating the arrow end in contact with the cutting disc flat surface while the motor is running to lightly abrade and smooth the end to 90 degrees.

Further advantages of the versatile 123 ALLHone saw system are a dremel type saw is mounted as illustrated by images showing the Ozito saw in situ and clamped and is also easily detachable so the saw is available for many other engineering duties instead of compared to other arrow saws whereby the saw motor is unusable for other work.

The 123 ARROW saw clamp has one 5mm hole throughout opposing feet and is able to be screwed or clamped down onto a bench and conveniently used for other work.

The parts are precisely slidably arranged upon a 30mm by 20mm rectangular aluminium tube that is supplied with.

The middle cradle bases are higher than the end supports so they are slidable.

Ozito saw motor not supplied is available at many builder and tool suppliers for less than $100 with accessories.

Available at www.bootsandgear.nz

ALLHone arrow fletcher

ll designed and made in New Zealand.

Will fletch helical (right hand and left hand)and straight vanes up to 3 inches Let us know your prefered type. Each set of extra three arms is only $5.

A screw combined with a lock nut extends through the handle and provides lockable adjustment for where you want to adhere the vanes onto the shaft’s elongated axis.

The end of the screw provides a rectangular protrusion available for slotting into the arrow’s knock within the handle and the arrow can also be fitted without the knock or pin.

A slidable collar with a tensioning nut is disposed adjacent to where the shaft is inserted into the handle aligns the three vane holding arms and functions by manually shifting the collar forward so the collar guides and folds the three arms into position and the vanes are in contact with the arrow shaft.

Once the vane holding arms are in place a cap that is flared is slid over the arrow and ends of the vane holding arms and this locks the arms in place providing contact pressure for the vanes to adhere.

The cap and the slidable collar tensioned by the nut pressures the vanes onto the arrow surface creating the best bond.

The arms clip in and out of the handle and easily can be swapped from helical to straight fletching arms. The arms slide along groves so it can fletch 6mm to 8mm OD arrows at approx 5 degrees.

Available at www.bootsandgear.nz

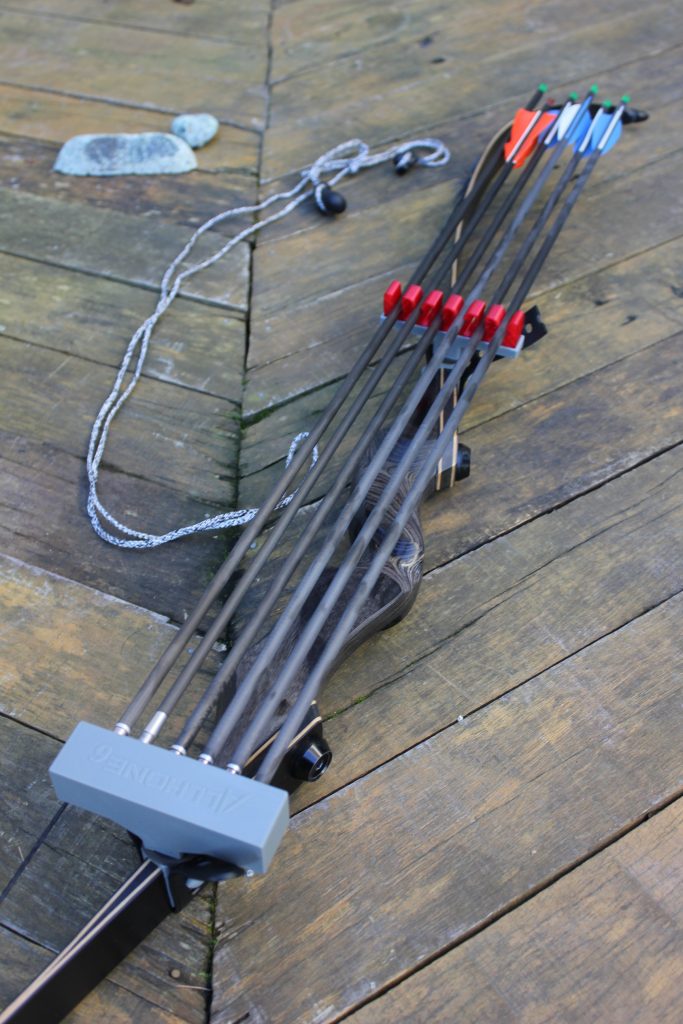

ALLHone Black Hunter 6 QUIVER

Bow quiver designed and made in New Zealand.

Made for the Black Hunter bow and its relatives. Holds up to 6 arrows.

Three optional red flexible arrow clamps designed to fit most outer diameter of arrows.

The red or grey Arrow clamps are interchangeable by manual removal from the clamp holder by pressing the replacement into the clamp holder until the groves fit the lips that securely retain the arrow clamp in place during all forms of archery activity and possible falls during hunting.

Quiet and does not upset the bow for accuracy.

Weighs only a mere 120 gms.

Built very strong with flexible PETG polymer.

Brackets have opposing pairs of hooks connecting onto tough elastic TPU straps that are manually tensioned around the respective limb adjacent to the riser and will not slip even after extensive target use at the range.

Easily removed from the bow and re-attached.

Each bracket screws directly into the arrow point basket and opposing arrow shaft holder allowing for exact adjustment of angle so all parts are perfectly aligned with the arrow shafts. Rotational movement is resisted by rubber washers. Do not over tension.

Works for both right hand and left handers by switching the brackets around.

TPU staps available in black or orange colour. These are tough elastic straps made for hitching things onto bike frames and packs for carrying extra gear. So for a few arrows they are overly strong and are readily available from most shops or online if ever a replacement is needed.

Available at www.bootsandgear.nz

ALLHONE SIKA Call

An improved Sika stag call from ALLHone NZ.

The whistle body and tube are screwed together so there is no possibility of them separating like other calls that use press together parts.

Chanel groove for lanyard attachment.

Doesn’t air lock when wet.

Weighs only 22 gms.

We made many many prototypes before we were happy with the tone.

Sika are related to Elk.

Novel clip-on belts,pockets and pack harnesses that holds ammunition. Very handy.

Features a very strong clip able to be removed by sliding the belt between the clip’s end for easy attachment and dettachment.

Easier to use than a closed loop yet just as reliably connected to the belt.

Remains on due to a hook at the end of the loop.

We guarrantee this wil stay on.

Extended tube protects the projectile from knocks so it remains aligned and prevents cartridges from being knocked out by impact with an object if you fall over or move through the bush.

Held in place by an elastic insert that has perfect tension to hold yet able to remove for quick reloading.

For handloads or different makes you can mark them individually with a permanent pen marker and able to see easy which is which for different ranges or Sika to reds for examples.

For 243, 260, 7mm08, 308 family

270, 25-06, 30-06 family

An improved Mallard call from ALLHone NZ.

Versatile call for greetings to feeding etc.

Channel groove for lanyard attachment with a loop hole to keep lanyard more secure.

Will not air lock when wet.

Option available to add your peronalized signature, please discuss what will fit onto the whistle part beside the ALLHone brand location.

#boots and gear #allhone